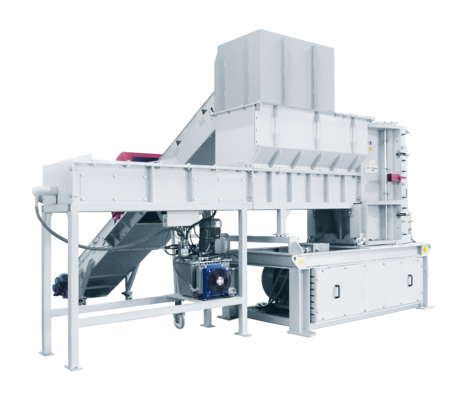

Nowy rozdrabniacz-granulator o charakterystycznej nazwie Polyplex firmy Hosokawa Alpine to nowatorskie rozwiązanie do rozdrabniania materiałów z tworzyw sztucznych wszelkiego rodzaju!

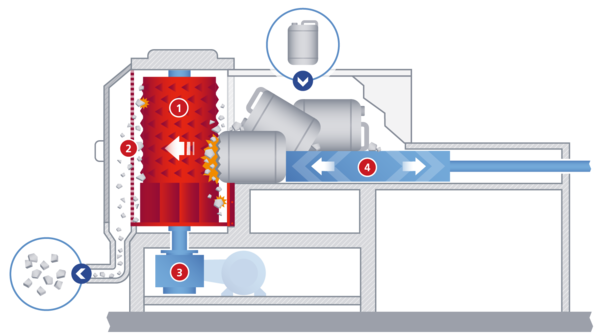

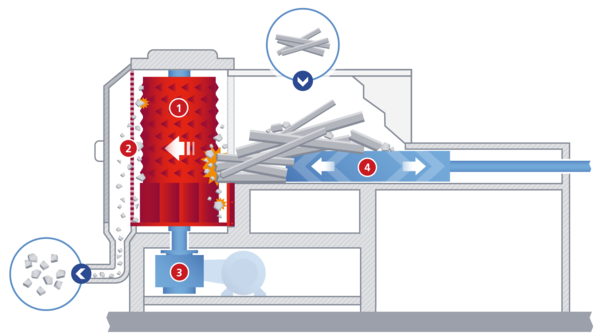

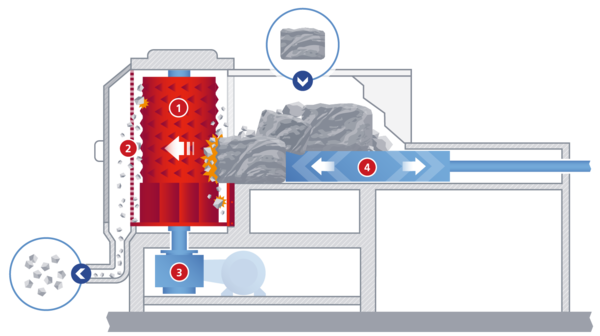

Oszczędzasz miejsce, czas i zasoby! Jak? Rozdrabniacz-granulator PPC Alpine Polyplex łączy dwa sposoby działania w jednej maszynie: pionowo ułożony wirnik rozdrabniacza z wirnikiem granulatora.

Koncepcja maszyny została dostosowana do Państwa potrzeb i wprowadzona na rynek w postaci urządzenia Polyplex – i to w atrakcyjnej cenie. W praktyce jednoczesne podawanie najróżniejszych odpadów z tworzyw sztucznych stanowi znaczną zaletę: wstępne sortowanie lub dozowanie materiału należą już do przeszłości!