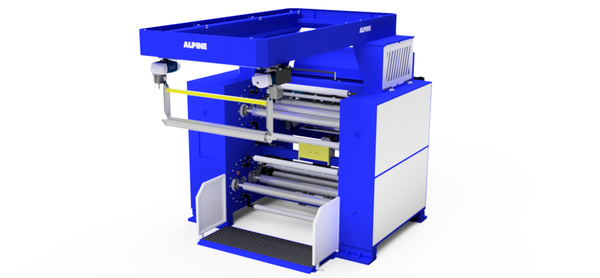

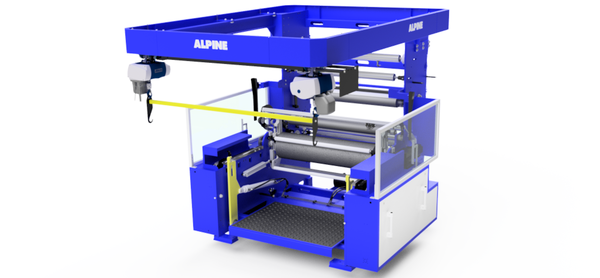

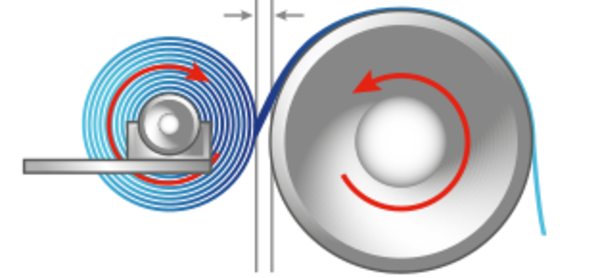

Czym byłaby misternie wyprodukowana folia bez odpowiedniej technologii nawijania? Od ponad 70 lat Alpine spółka zależna HOSOKAWA KOLB opracowuje rozwiązania dla idealnych rolek do nawijania folii:

- doświadczenie zdobyte na ponad 2500 wyprodukowanych maszyn nawijających

- ścisła współpraca z ekspertami od wytłaczania folii rozdmuchiwanej

- portfolio produktów, które oferuje optymalną przewijarkę dla każdego rodzaju folii