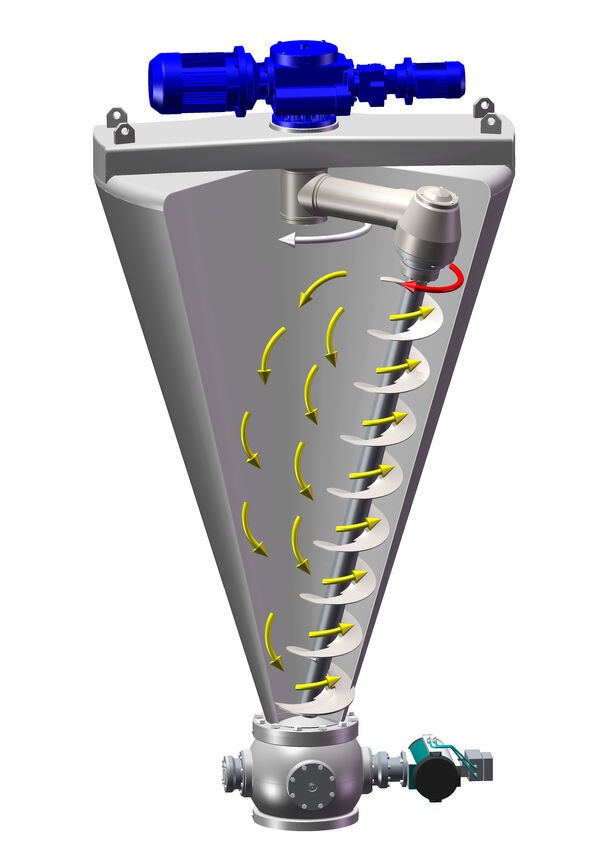

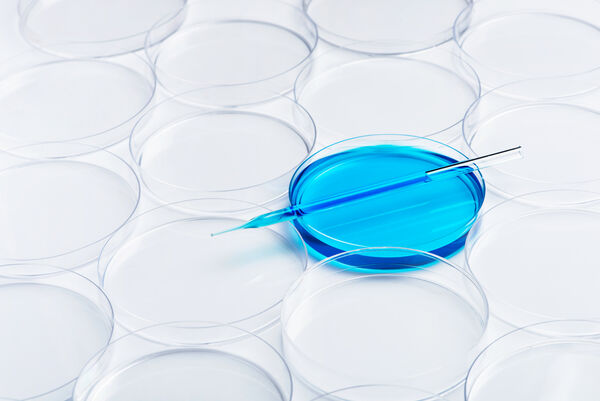

Hodowle komórkowe wymagają specjalnych podłoży. Sztuka wytwarzania dobrej witalności komórek i krzywych wzrostu leży w recepturze i prawidłowym zestawieniu składników. Po znalezieniu tej mieszanki decydującą rolę odgrywa właściwa obróbka. Suche podłoże musi być jednorodne zarówno pod względem wielkości ziarna, jak i proporcji składników mieszanki, tak aby nie tylko szybko się rozpuszczało, lecz również zawierało jednakowy i prawidłowy skład w każdej pojedynczej dawce. Delikatna i higieniczna obróbka podłoży hodowli komórkowych zapewnia ich wysoką jakość. Jednocześnie zakłady produkcyjne muszą być elastyczne i wydajne, aby móc codziennie produkować nowe partie. Wiąże się to oczywiście z łatwym i szybkim czyszczeniem.