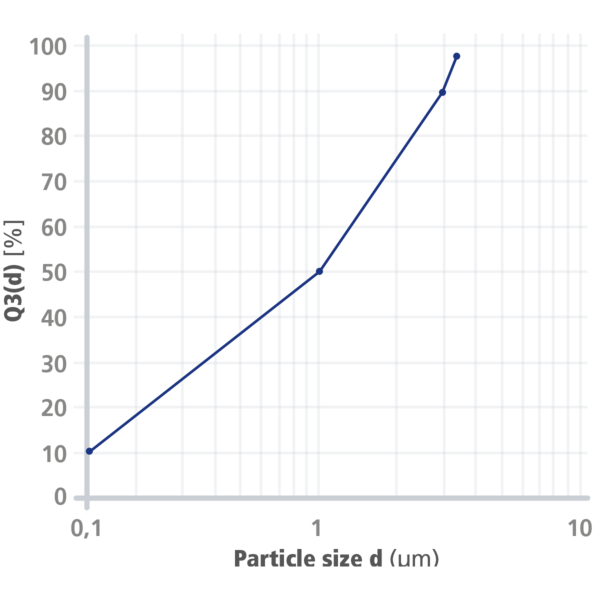

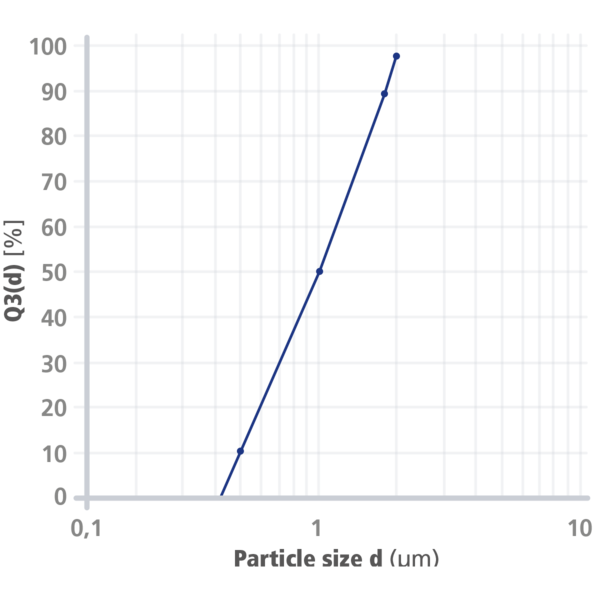

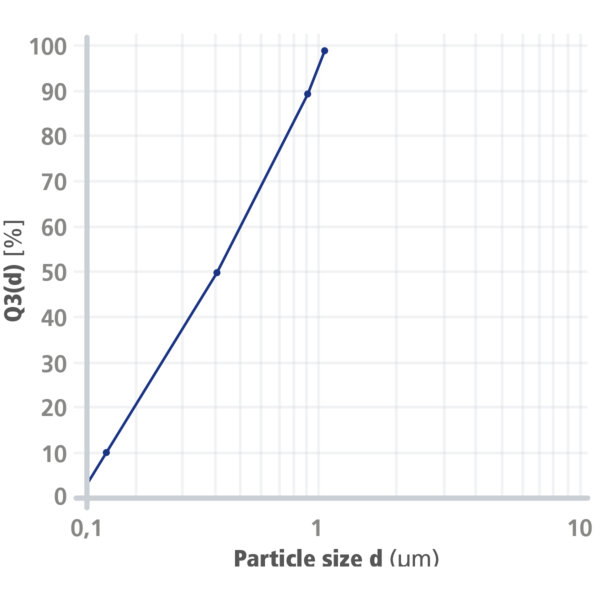

Proces klasyfikacji mielenia kulowego od dawna dominuje wśród klasycznych procesów mielenia twardych materiałów w obszarze zastosowań przemysłu szklarskiego i ceramicznego. Dzięki dostępności wysokowydajnych klasyfikatorów powietrznych z ochroną przed zużyciem ta technologia mielenia na sucho może obecnie osiągać znacznie mniejsze rozmiary cząstek, aż do d97 = 3. Ponadto, technologia procesów klasyfikacji mielenia kulowego w zakresie średnio-drobnoziarnistym d97 = 20 – 100 µm nadal ma swoje dobrze znane zalety, takie jak wytrzymałość oraz niskie koszty konserwacji i zużycia. W ostatnich latach procesy klasyfikacji mielenia kulowego były stale dostosowywane i optymalizowane, aby spełnić wszystkie wymagania dotyczące przetwarzania twardych materiałów. Dzięki użyciu kombinacji różnych klasyfikatorów powietrznych oraz systemów przesiewania możliwe jest wyraźne dostosowanie idealnie pożądanego rozkładu ziarna do zwiększonych wymagań stosowania. Obecnie wytwarza się bardzo wąskie rozkłady ziaren, np. dla szkła LCD do telewizorów lub telefonów komórkowych, lub też ze standardowego proszku wydziela się dwa wysokiej jakości produkty, które z jednej strony stosuje się jako glazurę, a z drugiej – w korpusie ceramicznym, uzyskując w ten sposób w każdym przypadku znaczną poprawę jakości.

W zakresie drobnoziarnistym d97 = 3 - 20 µm dzisiejsza technologia klasyfikacji w obiegu zamkniętym z młynami kulowymi umożliwia ekonomiczną produkcję, szczególnie w porównaniu z droższymi, często wciąż stosowanymi procesami mielenia na mokro.

Za pomocą mielenia strumieniowego wytwarzane są w znacznym stopniu wolne od zanieczyszczeń, ultradrobne proszki o stromej krzywej uziarnienia.

Quartz is an essential raw material for industries such as ceramics, glass and electronics, where its purity and physical properties play a crucial role in product performance. Achieving the desired fineness and particle size distribution is key to unlocking its full potential in these applications.

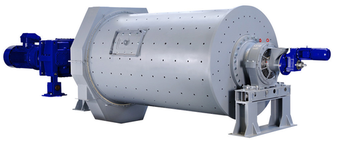

Our advanced ball mill systems, such as the S.O.-SF ball mill combined in direct or in double selection with the Alpine Stratoplex /Alpine Turboplex multi-wheel classifier, offer a cutting-edge solution for quartz processing. These systems are equipped with wear-resistant components like Al2O3 (aluminium oxide) linings and PU (polyurethane), which ensure long service life and low contamination of the end product. Key advantages of our dry grinding technology include:

- High whiteness levels: Preservation of the natural brightness of the quartz for optimum performance in sensitive applications

- Efficient and precise grinding: Consistent particle size control for enhanced product quality.

Our quartz grinding solutions provide the reliability and performance required for high-quality ceramics, pure glass formulations and advanced technical applications.

In the ceramics industry, zircon sand is used for glazes, with a basic distinction between two products:

Zircon flour, fineness d99 = 45 μm

Opacifier, fineness d50 = 1,0 μm

Zircon flour is usually produced with dry ball mills in combination with a classifier, while opacifiers are traditionally manufactured by wet grinding. However, with our innovative grinding system –featuring the S.O.-SF ball mill in combination with our ultra-fine Alpine Turboplex multi-wheel classifier in one step – we have revolutionised the production of opacifiers by introducing a fully dry process.

This dry grinding solution offers some decisive advantages over wet processing, including

- lower energy costs, as no drying is necessary

- steep particle size distributions without oversized particles

- easier handling without wastewater management

![[Translate to English:] Stratoplex ASP II](/fileadmin/_processed_/3/8/csm_ASP_II_Rendering_580bda0509.png)